The American Iron and Steel Institutes AISI Automotive Program continues to be the catalyst for engaging the steel industry the automotive industry and. High tensile strength and an optimised microstructure also give excellent fatigue properties.

Automotive Advanced High Strength Steel Market Size Share Analysis 2021 2030

It is used in making vehicle bodies car doors frames undercarriages MS chequered plate and bumpers due to its lightweight property.

. AHSS steels provide high-force absorption for bumper reinforcements while achieving major weight reduction. Dual-phase high-strength steel rails. The reason for this reputable feature is Hyundais Advanced High-Strength Steel AHSS.

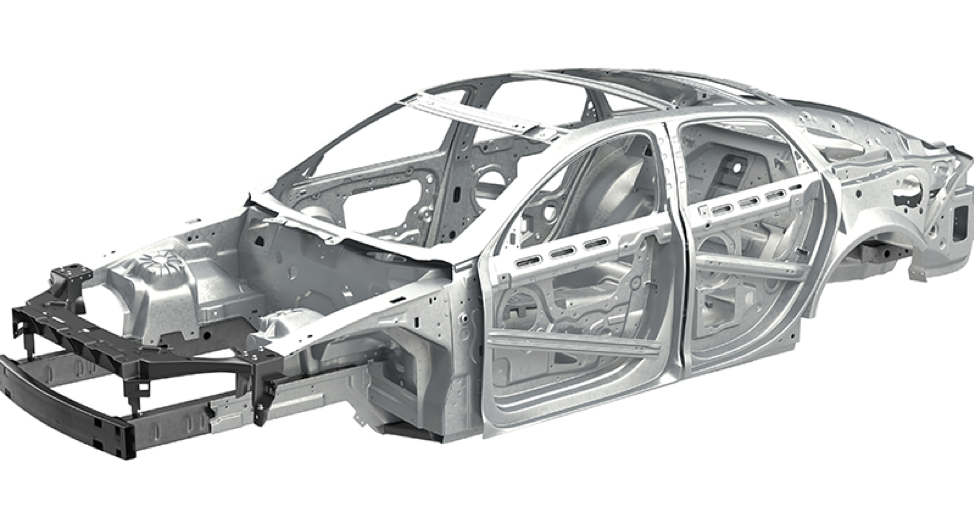

AHSS steel has also been introduced in all other vital areas of the car and many new cars are already composed of 30 to 40 percent AHSS. In the automotive industry materials used to form vehicle parts are chosen based on a number of important criteria among them strength ductility cost. Advanced high-strength steels AHSS are helping car manufacturers usher in an era of robust lightweight vehicles that improve fuel efficiency and lower emissions without compromising on safety.

The first classification method is a metallurgical group that provides certain amount of process information. And tailor-welded B-pillars between the front and rear door frames which help prevent intrusion into the passenger. Steel is the only automotive material that bridges the performancecost gap.

AHSS delivers high strength with good ductility especially for a cars structural elements. AHSS grades are typically produced by non-traditional thermal cycles and contain microstructural constituents whose mechanical properties can be altered by exposure to elevated temperatures. One is a metallurgical designation providing some process information.

The Fusion and Fusion Hybrid feature a number of advanced high-strength steel AHSS technologies including a lightweight high-strength steel body structure for added side and frontal impact protection. New grades of advanced. The long awaited 3 rd Gen AHSS which will be rolled out commercially in vehicles in late 2017early 2018 will only replace older AHSS not aluminium.

It is formable weldable and more economical than alloy steel. Suitable steel grades Consider Docol Martensitic M grades. Hyundai said that the AHSS provides a stronger and lighter framework for smoother aerodynamics.

The Korean automaker shared that the AHSS can be attributed to four characteristics. Advanced high strength steel is beneficial for several reasons including. In addition to its strength durability and dependability steel is also the key to recycling a car at the end of its long life as steel is continuously recyclable.

Looking closer at AHSS it can be seen to offer many advantages in chassis components. Advanced High Strength Steel Sheet Coil. Hence many car manufacturers are coming up with various solutions to enhance the AHSS for more safety performance and price.

Hyundai said that its AHSS wont let you down. This years new car models are set to be standard bearers for a generation of cars fortified by innovations from within the steel industry. This has been clearly demonstrated in the ULSAB family of research studies.

The introduction of Advanced High-Strength Steel AHSS to light vehicle body structure applications poses a significant challenge to organizations involved in vehicle repair. Advanced High Strength Steels for Cars. AHSS is strong light and produced with a reduced life cycle impact helping automakers decrease a vehicles life-long carbon footprint.

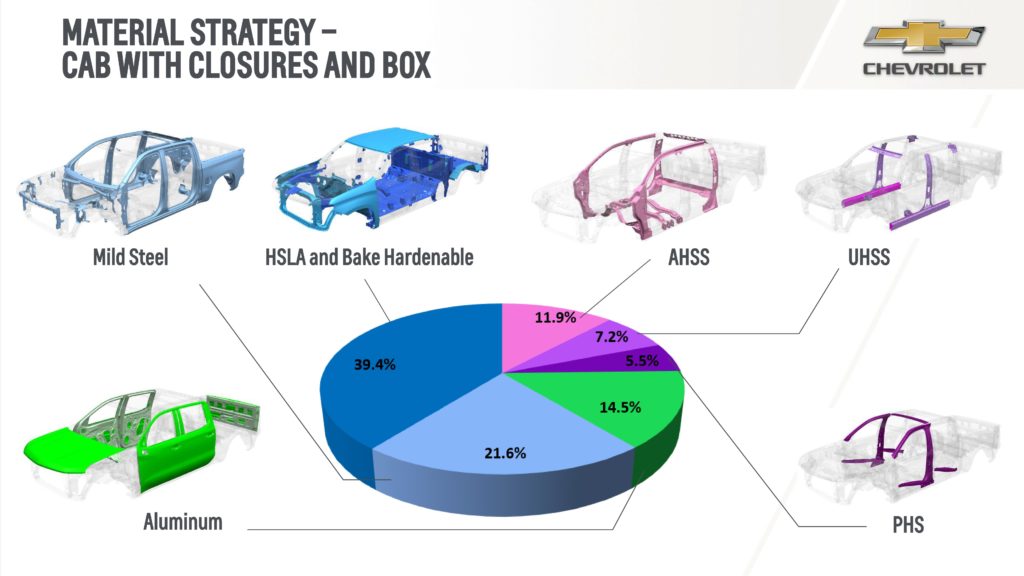

Americans depend on automobiles to keep families safe. What is clear is that aluminium and steel AHSS 3 rd Gen AHSS UHSS will be dominant in the future with each making up between 20 and 30 of a vehicles weight on average. The higher strength lets you use thinner steels.

Optimized steel body structures using AHSS can be constructed at little or no additional total system cost relative to a conventional steel body structure. The rest will be made up by. For this reason most cars today have a steel front end that can collapse like an accordion upon impact.

The body combines various high-tensile strength steel alloys and sits on a chassis that is stiffer and more durable thanks to the increased use of AHSS. AHSS still delivers performance. The AHSS is new generation steel that provides strength up to 2000 MPa and high durability.

The greater use of structural adhesives up more than 450 percent over the previous edition improves noise vibration and harshness NVH and contributes to the vehicles structural rigidity. General classifications include high- strength steel HSS low-strength steel and the latest AHSS steel. There are different ways to classify automotive steels.

And Advanced High-Strength Steels AHSS such as. Automakers use AHSS to make better cars The need for safer and economical vehicles has compelled automakers such as Honda BMW and Ford among others to invest in high-strength steel. The same steel used in automobile bodies this AHSS advanced high-strength steel allows you to fabricate high-strength parts using thinner material than you could with other types of steel.

In only a few years AHSS is predicted to make up 40 to 50 percent of the sheet steel used in cars contributing to a 5 percent reduction in total GHG Green House Gas emissions. Conventional high strength steels such as bake hardenable and high-strength low-alloy steels HSLA. Frequently the car OEMs goal is to achieve specific welding parameters or weldability of the AHSS by carefully specifying its chemical composition.

It has become the material of choice for passenger safety cage components like sill reinforcements A-pillars B-pillars side impact beams waistline reinforcements. These special steel chemistries let you use heating and cooling to vary the steel properties as you make parts from them. Steelmakers have developed steel grades that are both stronger and more formable.

Youngs model is high for steel and in combination with good formability it is possible to reach high stiffness in components. Automotive steels can be divided into a number of ways. Advanced high strength AHSS steel.

The tolerances for AHSS flatness are dictated by the auto OEMs need for shape accuracy in the final automotive component. Common designations include lower-strength steels interstitial-free and mild steels. Fewer emissions The use of AHSS contributes to a 5 reduction in greenhouse gas emissions.

Its sometimes called HSLA high -strength low- alloy steel.

Smdi More Than 65 Advanced High Strength Steel Vehicles Debuted In 2018 Repairer Driven Newsrepairer Driven News

New Volvo Xc40 Makes Extensive Use Of Ahss And Boron Grades

Automotive Steel Processing Ahss And Galvanized Steel National Material Company Steel Processing Facilities

0 Comments